Globalization, digital transformation and scarcity of resources: all these developments mean that the pressure on companies is ever increasing. Managers are faced with the challenge of supporting their employees in manufacturing, reaching new customers with innovative products, and bringing services to market faster.

The solution? Process automation - best for well-designed and flexible processes. Whether it's automatic washing machines, vacuum robots or coffee machines - machines are taking over more and more tasks not only at home, but also at work. Automation makes our everyday lives easier and saves us a lot of effort. But will machines eventually take over our jobs? We explain to you what is behind the automation of processes and how you can use the potential of Industry 4.0 for yourself.

What can be automated?

The principle of process automation is very simple: Do monotonous work faster and easier. Manual work steps that always follow the same, recurring pattern are reduced or completely eliminated. The goal is to make your work easier in this way. This way you can focus on difficult, exciting topics.

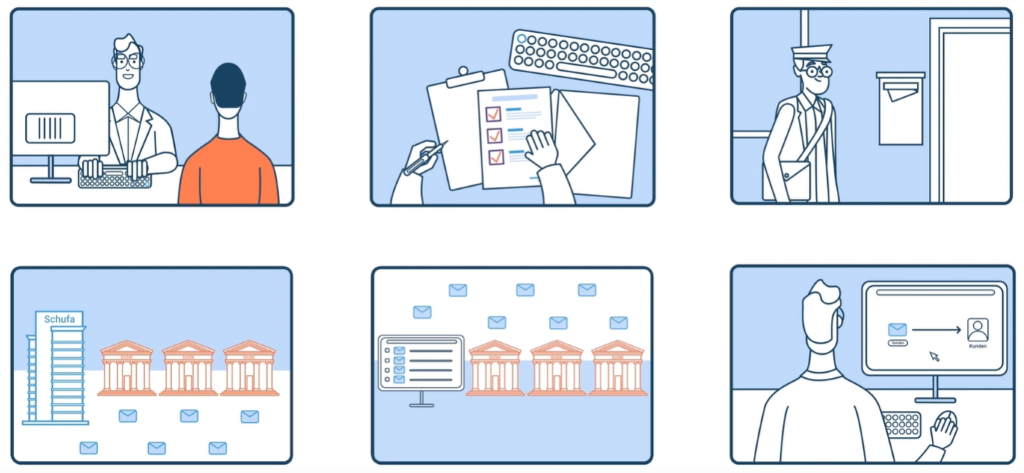

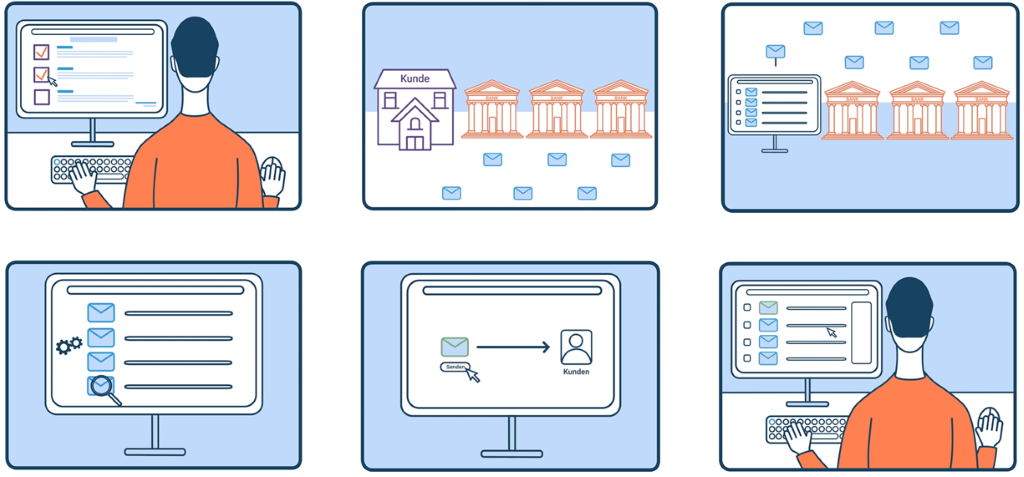

This principle can be applied to many areas. Let's look at the review of a loan application, for example. As a credit broker, you start in the manual process with a customer interview. You record the customer data, transfer it to the required forms and then apply for a SCHUFA report. At the same time, you request credit offers from various banks and compare them. You then send the shortlist with the best conditions to your customer. This is all rather time-consuming and tedious. So the question is: Which work steps can you save with the help of automation?

In a automated process the customer enters his data online in your system - so you no longer need to conduct a personal interview or transfer the data manually. After entering the customer data, it is automatically transmitted to various banks via digital interfaces. Loan offers and possible conditions are sent back to your system in the same way.

You can also be relieved of the task of evaluating the offers. You merely determine which criteria are decisive for the customer. A Machine Learning Algorithm checks and sorts the offers accordingly. The selection of the best conditions is then automatically sent to the customer. In this way, you save a lot of time and can concentrate on more important tasks such as personal consulting.

The question of whether machines will replace our work is as old as industrialization itself. From the first steam engine, to assembly line work, to manufacturing robots and the networked Industry 4.0: production processes have become increasingly automated and the proportion of manual work has decreased. With each new stage of automated production, certain occupations were displaced, but at the same time also countless new job roles created.

Industry 4.0: Automation in manufacturing

The more processes are digitized in industry and business, the more interfaces are created between the various people and machines involved. With the networking of systems, digitization is opening up new potential, particularly in production: The Internet of Things (IoT), human-to-machine communication and production facilities that are becoming increasingly intelligent are heralding the fourth industrial revolution: the Industry 4.0.

Industry 4.0 describes the comprehensive digitalization of industrial production. Automation forms the basis for this. Because the special feature of Industry 4.0 compared to traditional production lies in the Networking and sensor technology of the entire manufacturing process. Sensors like cameras, Motion detector or RFID chip generate information about the product and the current status of the machines. Through networking, machines now report to you independently, for example, when they need new material or detect problems.

The collected data is then processed by intelligent systems, for example using machine learning or even classical programming. This ensures that production runs correctly and efficiently. Predefined production sequences mean that the machine knows every necessary process step. The processing and evaluation of the data provides the next action steps as a result. These are fed back to the respective machines. In production, for example, these are manufacturing machines, robots or motors. These ensure that the materials are processed into the corresponding products.

Networked production makes it possible to manufacture completely individual products at prices that were previously only possible in mass production. Let's assume, for example, that you want to put together an individual muesli for a customer. Networking makes it possible to digitally query and store your customer's wishes via an interface. The muesli container receives an individual customer ID on an RFID chip. Using this number, you can assign the container to this customer at any time.

But how does the filling station know how to put together the muesli for our customer? This is where the sensor technology helps. In addition to the customer ID, all the information about the customer's wishes is also stored on the RFID chip. The filling station can read the chip with the help of sensors. In this way, the machine knows which steps have already been carried out and whether or not it needs to fill the container with the corresponding ingredient. With the help of automation and Industry 4.0 technologies, a completely customized muesli can be put together quickly and cost-effectively.

Automation and jobs: Will people be replaced?

Experts believe that around 50 percent of today's jobs will be partially automated. Machines and technical systems will take repetitive, laborious tasks off your hands. Only five percent of jobs will be fully automated with today's technologies, according to experts.

Automation is thus revolutionizing the job market. Repetitive tasks will give way in favor of creative problem solving and create space for strategic and conceptual work. Automation thus creates large quantities of products faster and more cost-effectively - and with consistent quality. The advantages of automation are therefore clear:

- Consistent quality

- high precision in execution

- high speed and quantity

- Work at any time of day

Tomorrow's jobs will change. You will increasingly work together with machines in an automated working world. Automation does not necessarily mean that people will be completely replaced. The real benefits lie in productivity and efficiency. We are talking about the Automation paradox: The more efficient the automated system, the more decisive the use of humans. Overall, you as a human being will be involved less often, but the importance of your commitment increases. Training and lifelong learning will therefore become all the more important. This makes you - more than ever before - your company's greatest asset.

Do you also want to automate your working environment and let machines take care of recurring processes? Feel free to contact us and we will help you and your company to exploit the potential of automation and pick up speed for the fourth industrial revolution.

Source: McKinsey (2020) " The imperatives for automation success“ [06.01.2022]